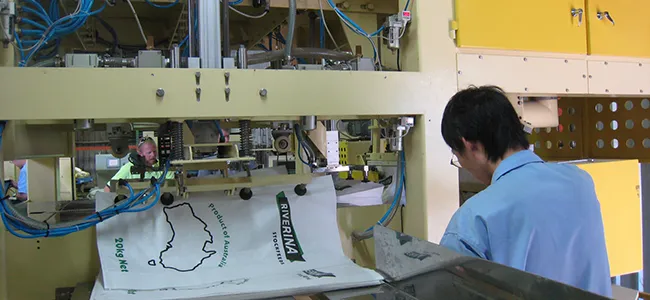

Equipment Maintenance, Upgrades, and Spare Parts Supply

We have a professional and experienced technical team capable of providing comprehensive and precise upgrades and modifications for various outdated packaging automation systems. However, since the condition of each piece of equipment can vary, the upgrade solutions, processes, and required investments will be determined based on the specific situation. If you have such needs, please feel free to reach out to us. We will arrange for our specialists to contact you and offer detailed, practical solutions tailored to your requirements.

During equipment operation, wear and tear on components is unavoidable. To minimize downtime risks caused by component failure, we offer spare parts and replacement services to ensure the continuous and stable operation of your equipment.

- Spare parts for two years of use can be shipped at any time (additional costs apply).

- For parts beyond two years, customers are required to pre-order based on our provided two-year spare parts list.

We have established a work order record system for all products sold under contract. We ensure the production of structural components in-house for reliability, while some externally purchased components may be subject to brand upgrades. In such cases, we provide early warning inventory notifications and alternative solutions. We offer free technical support for routine inspections and repairs via phone. For on-site assistance, a nominal travel fee and normal attendance allowance may apply. We also provide the option of an annual paid maintenance contract service.

During the warranty period, any quality issues caused by factors other than human error will be resolved by free part replacement (except for consumables and parts subject to wear). Consumables and wear parts come with complete usage and operation manuals, and we provide a two-year spare parts list. Customers can also purchase spare parts directly from LIMA or from the market, as applicable, according to the standard and model.

We offer long-term affordable pricing for spare parts, ensuring a steady and cost-effective supply of commonly used components.